What’s the difference between an off-road vehicle and an adventure vehicle? In our opinion, it’s the ability to carry the gear you need for self-sufficiency in a secure and organized manner.

Most vehicles come from the factory with the bare minimum of tie-downs and plenty of wasted space. The key to a good setup is finding products that utilize these unused spaces and allow for flexible storage.

When it comes to cargo management, there are several great companies out there to choose from. One of those companies is veteran-owned and Utah-based American Adventure Lab, or AAL. The company has been innovating since 2018 with the its halo being the Wrangler JL. Other applications include everything from pickups to Ford Broncos, and even a few adventurous CUVs, including Subarus.

American Adventure Lab’s mission of “advancing the development of adventure vehicles” manifests itself in every product the company makes out of its St. George, Utah, manufacturing facility. Obsessive with light-weighting, aluminum construction, and tight tolerances, AAL products are designed to be additive in nature to adventure vehicles, with a robustness designed for off-road excursions and a modularity designed for just about any use case.

For example, the American Adventure Lab M.A.S.S. (Modular Adaptable Storage System) is a base plate made from durable and corrosion-resistant 5052 aluminum, which on its own features flexible tie-down positioning via M.A.S.S. connector holes for different gear loadouts.

However, the M.A.S.S. system also supports a range of slides and stackable drawer options of various sizes that can be configured in dozens, maybe even scores, of different arrangements to fit the needs of adventurers and maximizing their organizing potential.

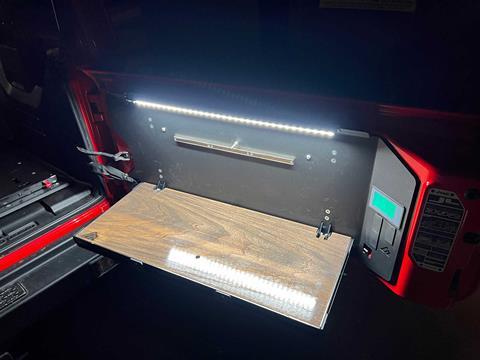

Another AAL product is the VersaTable, which is one of the most feature-packed tailgate tables on the market. Devoid of cable supports that could get in the way, the VersaTable’s work surface can be ordered in either sealed bamboo or poplar wood, and it incorporates magnets on the backsplash to hold knives and other utensils to free up the table surface. When stowed, the table’s underside becomes a MOLLE panel with additional M.A.S.S. connector holes.

The VersaTable is wired with an LED strip light to illuminate the work area and has an integrated trash bag hook. Options include a cutout for a battery monitor, a bottle opener, or a series of switch blank cut-outs to mount multiple Contura 2 switches.

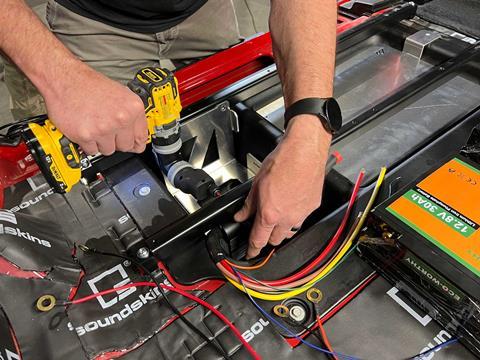

AAL also offers a slew of electronic products, such as auxiliary battery setups on Wranglers, Gladiators, Broncos, and other popular vehicles. On the Wrangler Rubicon 392, for example, AAL’s auxiliary battery system features two 30Ah lithium-ion batteries mounted in the rear underfloor storage cubby and wired in parallel for a total of 60Ahs of power.

That’s enough to power a fridge like our large Dometic CFX355IM for a full two days before needing a recharge. When paired with a Redarc BCDC battery charger, the batteries can be charged by the vehicle’s alternator or with solar panels.

Optionally, the auxiliary battery system can be mated with a multi-circuit fuse block for added electrical circuits, such as lighting.

American Adventure Lab has another popular product for the Wrangler in the underseat ARB compressor mount. In the V6 and 2.0T-equipped Wranglers, the rear cubby is large enough to house an ARB CKMTA12 twin compressor and a 50Ah battery, but in the 392 the cubby is only large enough for the batteries, so AAL developed an under-seat mounting bracket that integrates the ARB switch, air chuck, and compressor all on one mount that can be installed on either the driver or passenger side.

Across the product line, AAL offers a slew of powdercoat options to further customize its products, and their universal offerings ensure the largest swath of vehicle compatibility. Follow along with the numbered steps to learn what’s involved with outfitting a Jeep Wrangler 392 with all of the American Adventure Lab products discussed in this story, but be sure to visit the website for a look at the entire catalog and which products are right for your adventure rig.

Sources

American Adventure Lab

americanadventurelab.com

ARB

arbusa.com

Dometic

dometic.com

Redarc

redarcelectronics.com

Access More Great Stories!

This article originally appeared in OVR Issue 03. For more informative articles like this, consider subscribing to OVR Magazine in print or digital versions here. You can also find the print edition of OVR at your local newsstand by using our Magazine Finder.

2 Readers' comments