Steering has always been a bit of an evolving issue for the Wrangler JL.

The original JLs came equipped with an aluminum steering box that caused the off-road industry and customers fits before it was eventually upgraded to a more heavy-duty cast iron box. Many JLs still come with aluminum knuckles, and while they haven’t proven to be a liability for most users, there are instances of wallowed-out ball joint and tie rod tapers, or even outright failures, by those doing more moderate to hardcore wheeling.

Even Jeep has recognized these problems that can result in sloppy steering and equips certain models, such as the Gladiator Mojave and Wrangler Rubicon 392, with factory cast iron knuckles.

Regardless of which version of the stock steering setup that your Wrangler or Gladiator is equipped with, there is always room for improvement. When off-roading, a major area of vulnerability for the Jeep Wrangler and Gladiator is the steering linkage and stabilizer. The stock setup hangs down below the axle centerline, leaving it exposed to damage from rocks and terrain. We’ve replaced countless stabilizers over years, and more than a few factory tie rods.

To combat this, there are many heavy-duty tie rod options on the market, and these tie rods are designed to take a hit and are less susceptible to damage. Additionally, there are companies offering high-clearance steering kits, or flip kits, that drill out factory knuckles and re-locate or “flip” the factory tie rod on top of the knuckle mount, improving clearance.

These kits can work well, but they are not compatible with stock suspensions, aren’t always reversible, don’t always come complete, and can cause other component interference issues upstream of the tie rod.

Rock Jock by John Currie, the new name for a familiar company and product line, tried to solve as many of these issues as possible with the company’s new High Steer Knuckle Kit. Unlike some of the other offerings in the market, Rock Jock provides a fully engineered solution with everything needed to transform your Jeep’s steering without having to piece everything together from multiple sources.

Their specially developed high-steer knuckles are designed to exceed the strength of the factory units and are offered for use on any Jeep Wrangler (JL) or Gladiator (JT), regardless of whether it is equipped with the standard or the wide-track factory axles. Made from high-quality cast iron, Rock Jock’s knuckles incorporate adjustable steering stops and are completely bolt-on.

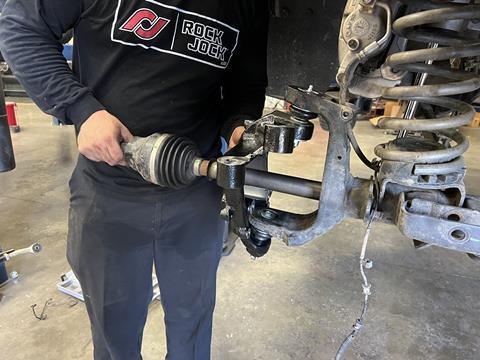

To simplify installation, the high-steer knuckles reuse all of the stock wheel end components, including ball joints, unit bearings, brakes, dust shields and axles.

Rock Jock’s High Steer Knuckle kit is designed to be used with lifted Jeeps and raises the tie rod position by 2.75 inches and the drag link by 2.5 inches, restoring factory steering geometry to vehicles with mild lifts and improving it greatly for vehicles with moderate lifts. The Rock Jock provided tie rod checks in at 42mm (1.625 inch), which is slightly larger than the 40mm stock tie rod, and is constructed of chromoly tube with 1-ton-sized forged steering ends. Repositioning the tie rod higher means it no longer hangs below the bottom of the axle tube where it is vulnerable to rock hits.

The steering stabilizer is also repositioned out of harm’s way with a relocation bracket on the axle side that it shares with the trac bar. Rock Jock also offers all the necessary provisions for anyone looking to run ram assist with this kit.

For those interested in upgrading to an adjustable trac bar, Rock Jock has an excellent choice in their optional forged chromoly and organically shaped Johnny Joint Adjustable Length Front Trac Bar.

This bar will allow the user to center the front axle, and, like the drag link, is shaped for maximum stiffness and clearance. It features a greaseable Johnny Joint rod end on the frame side and a Flex Axis rod end on the axle side. There is enough adjustability in the part to be used on stock-height rigs.

One of the challenges with developing a high-steer kit, especially on the JL platform, is the limited amount of clearance between components, especially at full compression. At the heart of this kit, Rock Jock includes their Currectlync forged chromoly drag link. Utilizing an innovative design, the drag link’s organic shape allows for increased up-travel by “nesting” with the tie rod at full bump.

After learning everything we could about the Rock Jock high-steer kit, we were excited to get some first-hand experience to see if it lived up to the claims. For this install at Rock Jock’s Corona, California, facility, we offered up our ’23 Jeep Wrangler 392 with the full American Expedition Vehicles JL370 package, which is equipped AEV’s exceptional 2.5-inch suspension.

While this kit works incredibly well, the Bilstein/AEV steering stabilizer is definitely in a location susceptible to damage, and as with all lifted Wranglers, we are always open to improving our steering performance. The Rock Jock kit also had the advantage of allowing us to center our front axle, and because the 392 XR package already uses extended bump stops, we didn’t have to limit our up-travel.

The one caveat worth noting is that the Rock Jock setup was designed to work with a factory stamped diff and not our iron AEV cover. Because we wanted to keep the protection of our front AEV diff cover intact, it had to be milled slightly to allow the steering stabilizer end to recess at full lock to the driver’s side.

Thanks to Rock Jock’s adjustable steering stops, we dialed back our steering lock by a practically unnoticeable 1/8-inch, which we felt was a good compromise to make everything work together.

We also took the opportunity to upgrade our factory ball joints. Initially we used Spicer’s upgraded Performance Ball Joint Kit, but because our 392 has the CV axles, there was not enough clearance to grease the bottom joint. Spicer’s grease fitting sits atop the ball joint, where it is a tight fit with the CV’s housing.

After trying multiple needles and tools, our ultimate solution was to invest in a set of Dynatrac HD ball joints, which have a grease fitting on the side of the ball joint, curing any access issues.

After the install was complete, we immediately noticed an improvement in steering that only improved further as the ball joints broke in. We’ve found the Jeep to be more directionally stable, with less wander, and just overall more pleasurable to drive, especially on the highway. The addition of the stiffer drag link tightens up the feel of the front end and allows the suspension and stabilizer to do their job of soaking up movement. All of it works together to make the steering feel more precise.

Off-road, there is less kickback in the wheel and we are no longer stressing about errant rocks just waiting to take out our steering components. In both everyday on-road driving and in taking on more technical trails, our Jeep is less susceptible to trail damage and our confidence in traversing rugged terrain has improved.

After a couple thousand miles, including over 250 of them off-road, we have zero hesitation in recommending this setup for any Jeep owner. Read on as we walk you through an overview of how to upgrade your Jeep’s steering to Rock Jock’s high-clearance setup.

![]()

Sources

Adventure Offroad

adventureoffroad.com

Dynatrac

dynatrac.com

Rock Jock By John Currie

rockjock4x4.com

Spicer

spicerparts.com

Tell us what you think about this article by commenting below. More Great Info! This article originally appeared in OVR Issue 06. For more informative articles like this, consider subscribing to OVR Magazine in print or digital versions here.

No comments yet